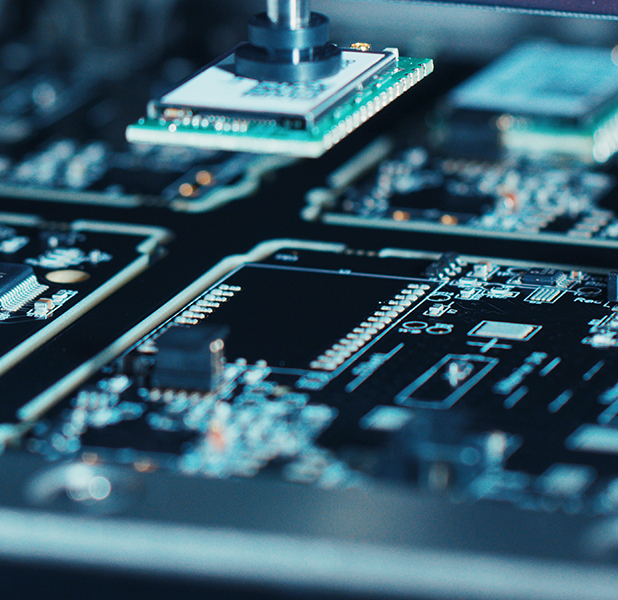

The efficiency of the surface mount technology (SMT) process hinges on the strategic sequencing of electronic components on the printed circuit board (PCB). An inefficient sequence can significantly prolong the assembly time, impacting overall productivity. To overcome this challenge, advanced AI algorithms are essential for analyzing PCB layouts and determining the most effective component placement sequence.

*Surface Mount Technology (SMT) is a method in electronics manufacturing that involves directly mounting components onto the surface of printed PCBs