- Semiconductor

- Optimization

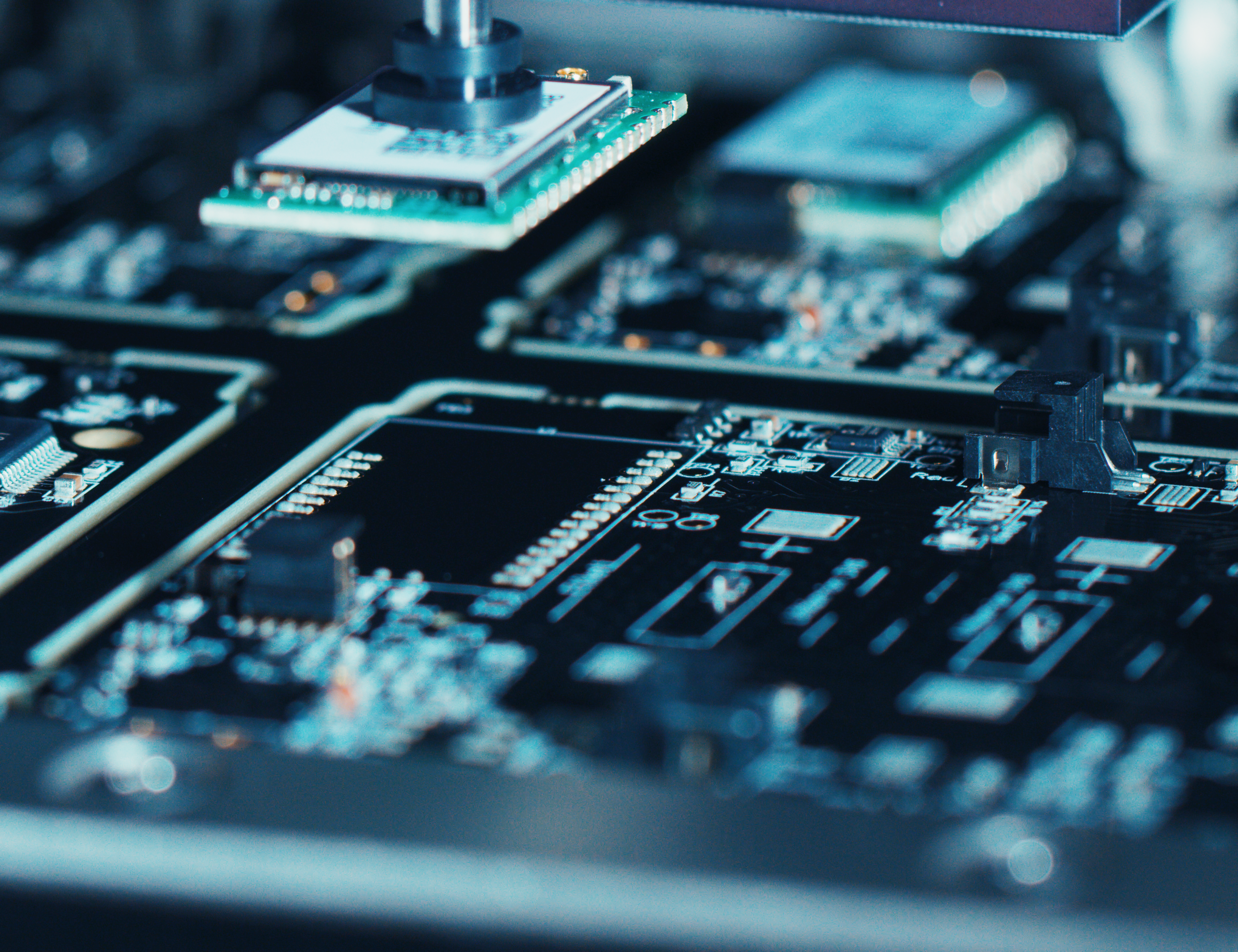

Chip Design Automation: 85% Faster Execution, 49% Better Performance

Boost operational efficiency with AI-based simulators and reinforcement learning agents for automated optimal component placement in custom ASICs.

READ MORE